Time to do the seat base now.

The foam needs a fabric covering underneath so that the webbing straps

don't cut into it. Don't know what would have been original for 1972. I

had this burlap on hand, so that's what I used.

Where the seat cover center panel will fit into the depressed area in

the cushion, contact cement is applied to the corner edges of the foam,

the lengthwise seams in the cover, and the center panel. It's important

not to over-apply the glue. It mustn't soak deeply into the fabric or it

could collapse the padded pleats. Just brush sparingly over the

surface.

Before the cover and seat foam can be attached to the seat frame, the

seat back should be temporarily assembled to the seat base frame so that

the alignment of the bottom covering center panel can be aligned to

match the center panel of the back covering. When the best position is

found, then the bottom cover and frame are marked for reference.

The bottom cover needs to be cut in several locations for wrapping

around the frame. Cuts are made where the covering can be folded under

so that there's not a raw edge visible.

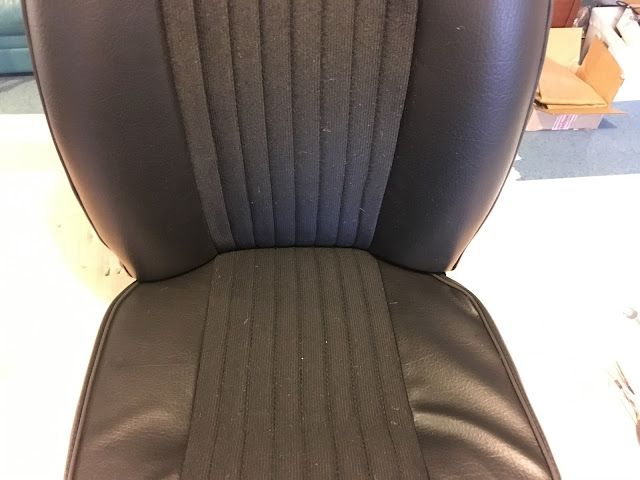

Job complete!

No comments:

Post a Comment