Now that I have a drivers side floor, I want to temporarily refit the

driver's seat so that I can more easily move the car around under its

own power.

When I got it, the drivers seat bottom was totally collapsed, so it was

like sitting on the floor. Besides, it was crusty and I didn't like

sitting on it.

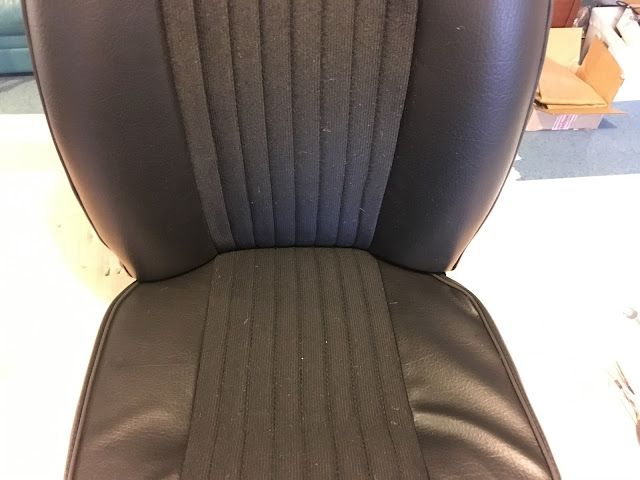

So, this is the first seat to get re-upholstered. I got the seatback done today.

Don't forget to lube the seatback recliner mechanism. I use a sticky

motorcycle chain lube for jobs like this. It sprays on thin to

penetrate, then dries to a thicker film that stays put.

New back stiffener card attached with tape and two screws.

The new foam gets wrapped around over the back stiffener, and glued to it.

The new foams have a hard edge from the mold parting line. This would

show through the upholstery as a sharp line. So I sanded the edges to a

soft, rounded contour.

With the seat back cover installed, the contour flows nicely already, but it will smooth out even more after it settles with some time. Wrinkles are from the packaging of the seat cover during shipping. Hopefully that will smooth out on its own.

The center of the seat cover fits deeply into the back,

showing pronounced side bolsters. The center area is glued to the foam

to achieve this. It is an important step that is skipped far too often.

Keeping the original headrests for now.